Tactical Tool & Die

Welcome to Tactical Tool & Die! ~ a division of Rebling

We specialize in crafting high-quality plastic injection molds, dies, fixtures, and gauges, with a primary focus on serving the defense industry, firearms, and munitions. With decades of experience, our team is dedicated to providing exceptional manufacturing and repair services that meet the rigorous standards of our clients.

Our Services:

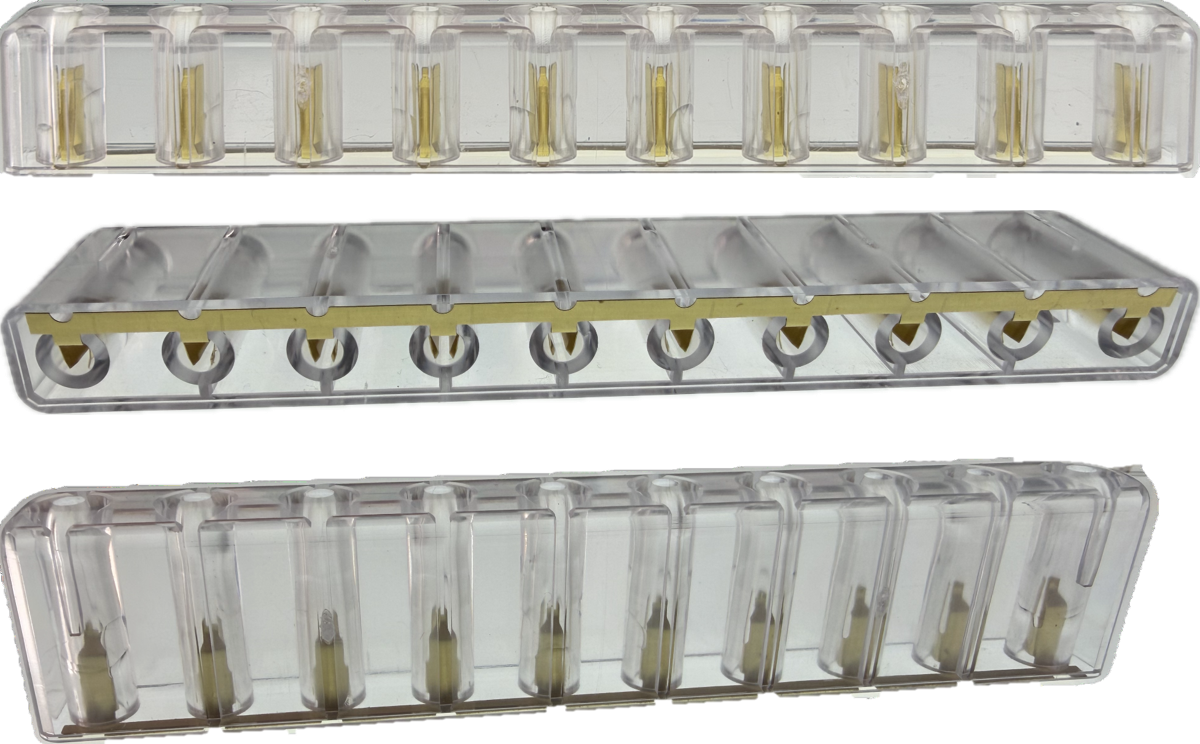

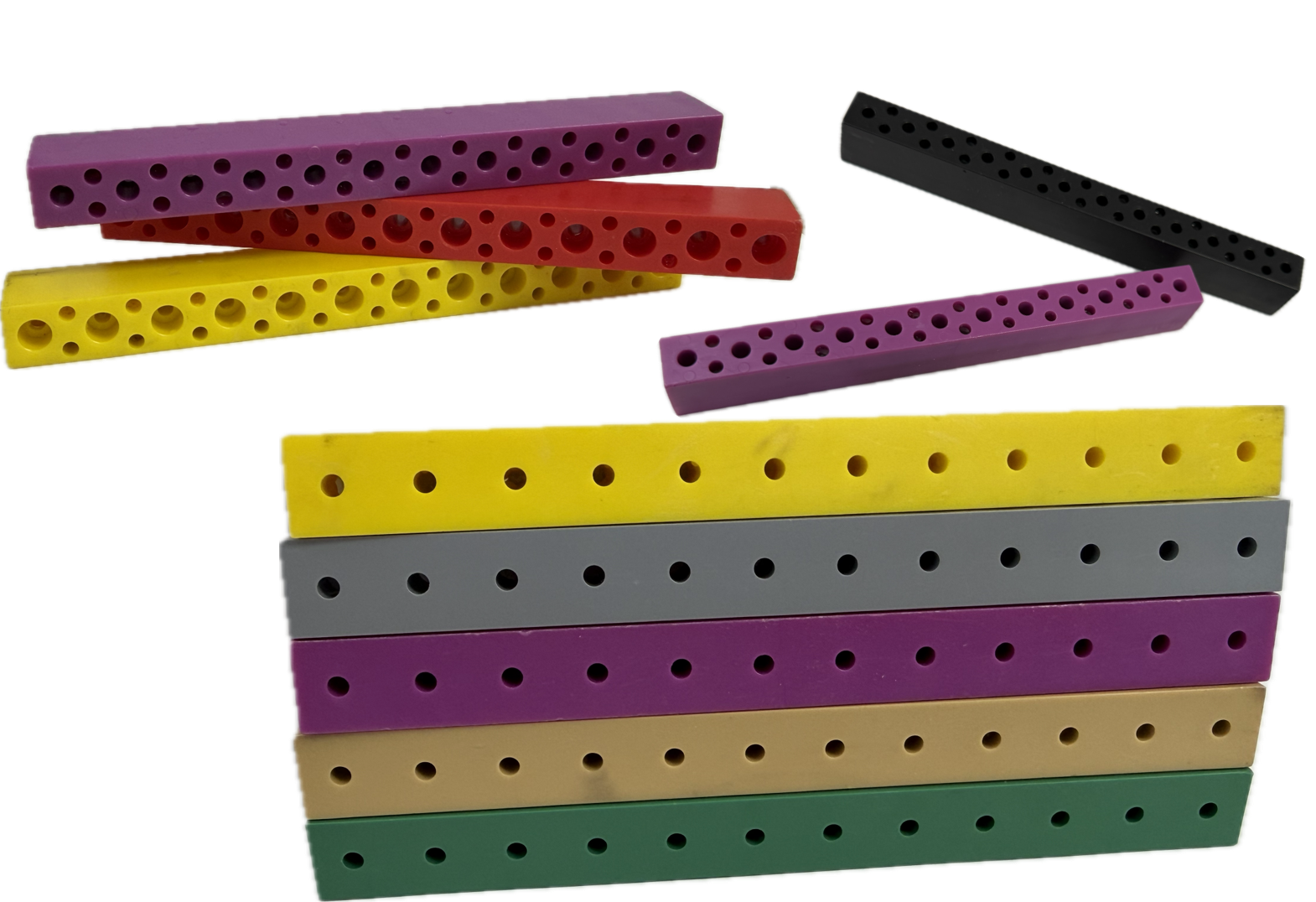

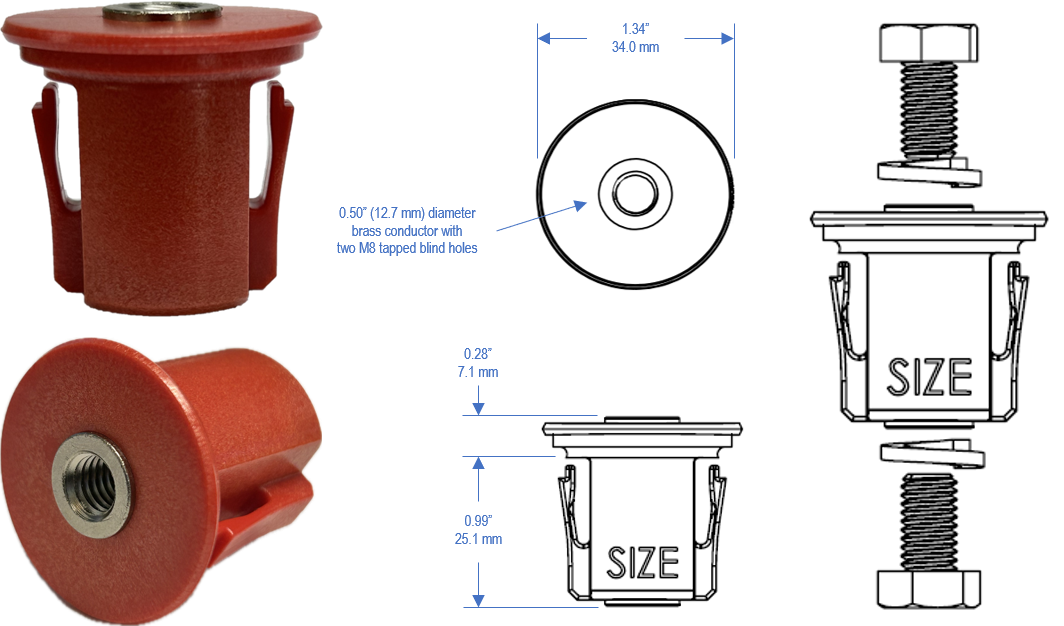

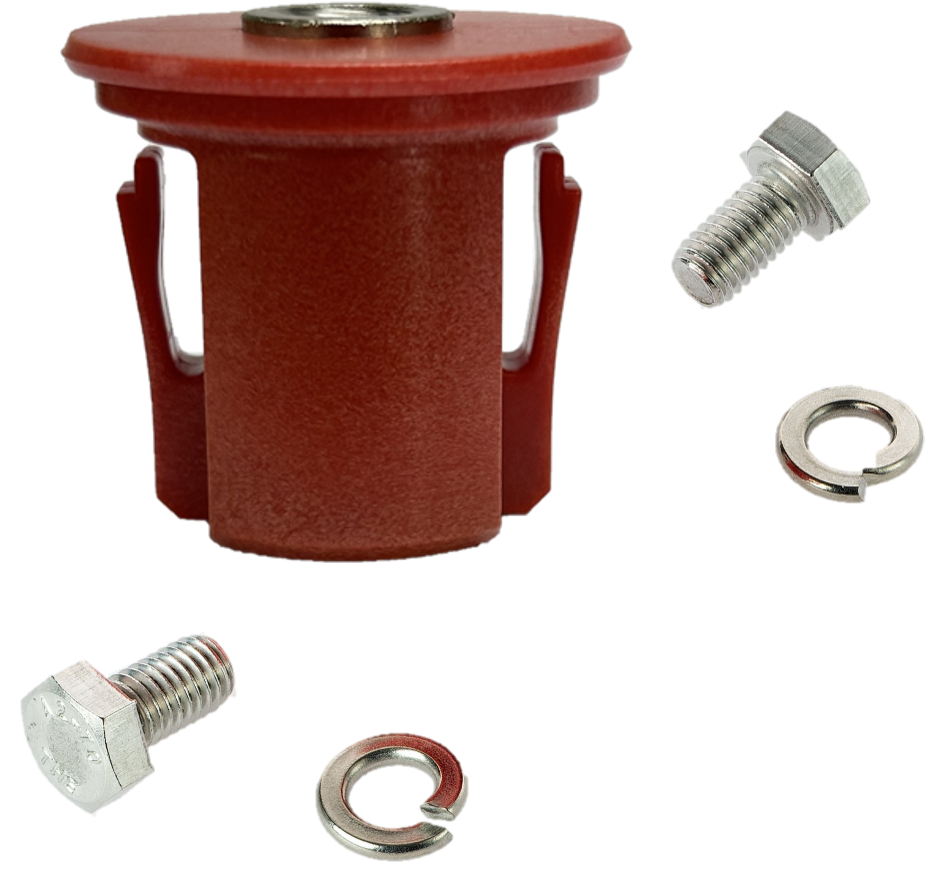

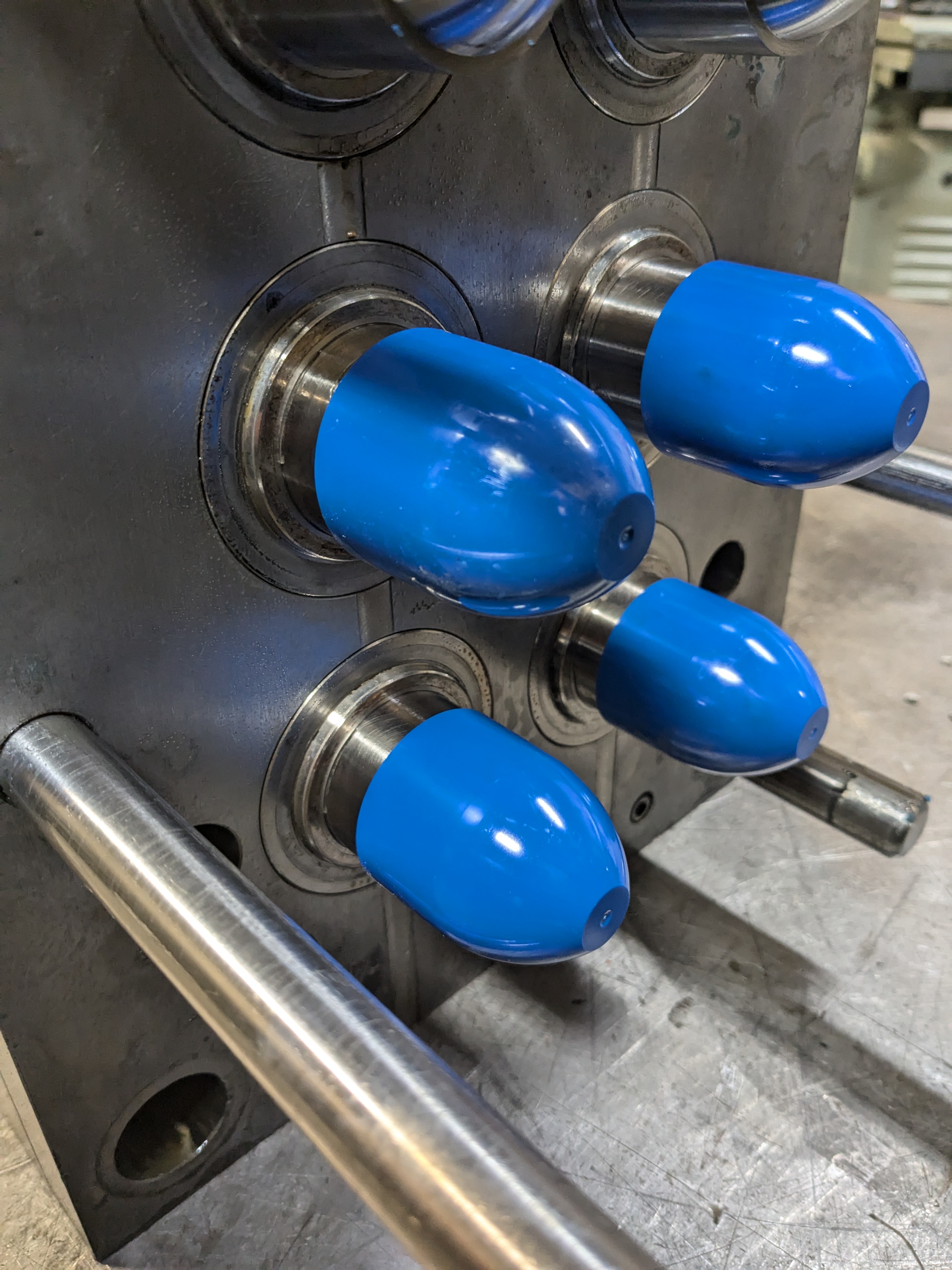

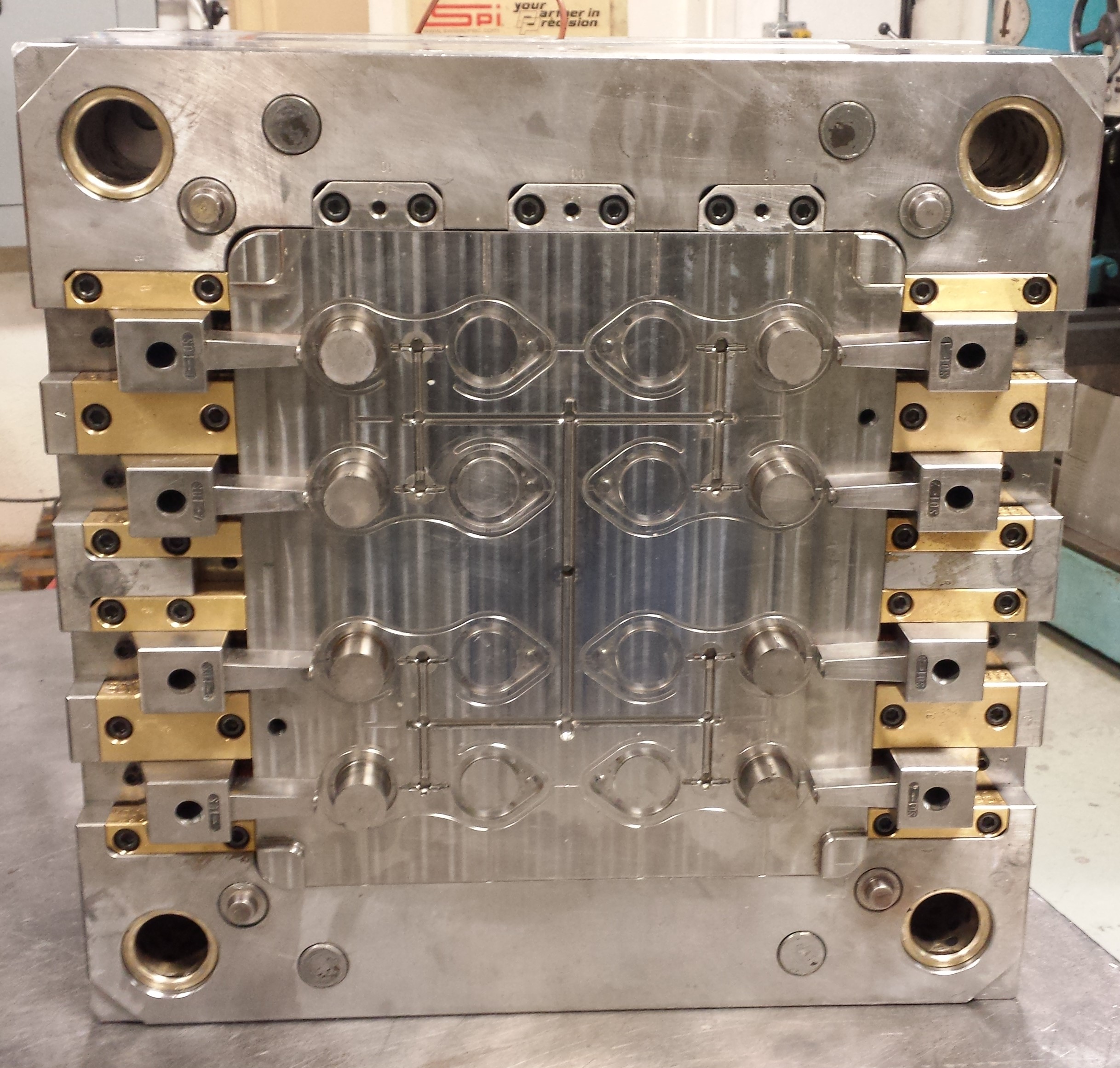

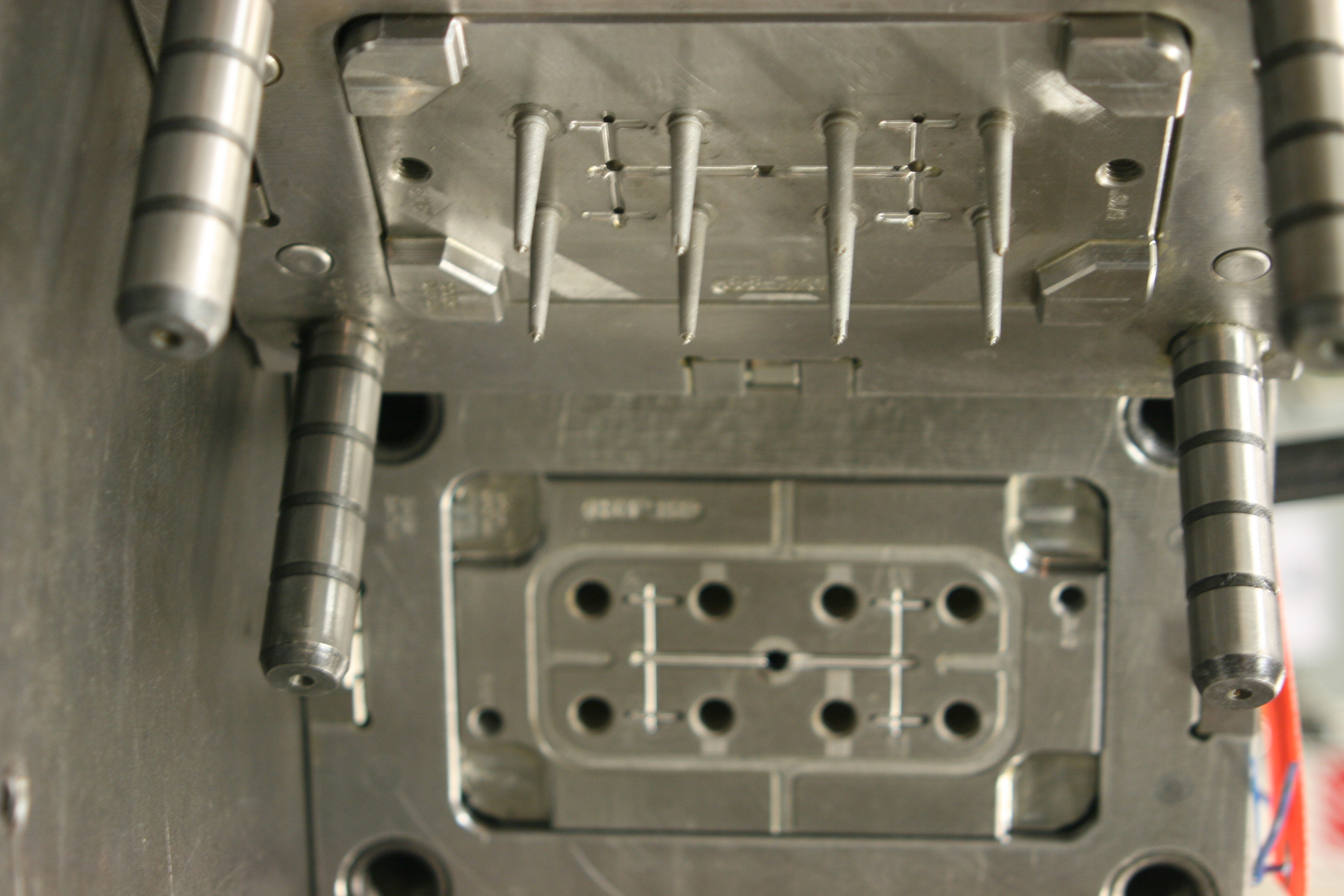

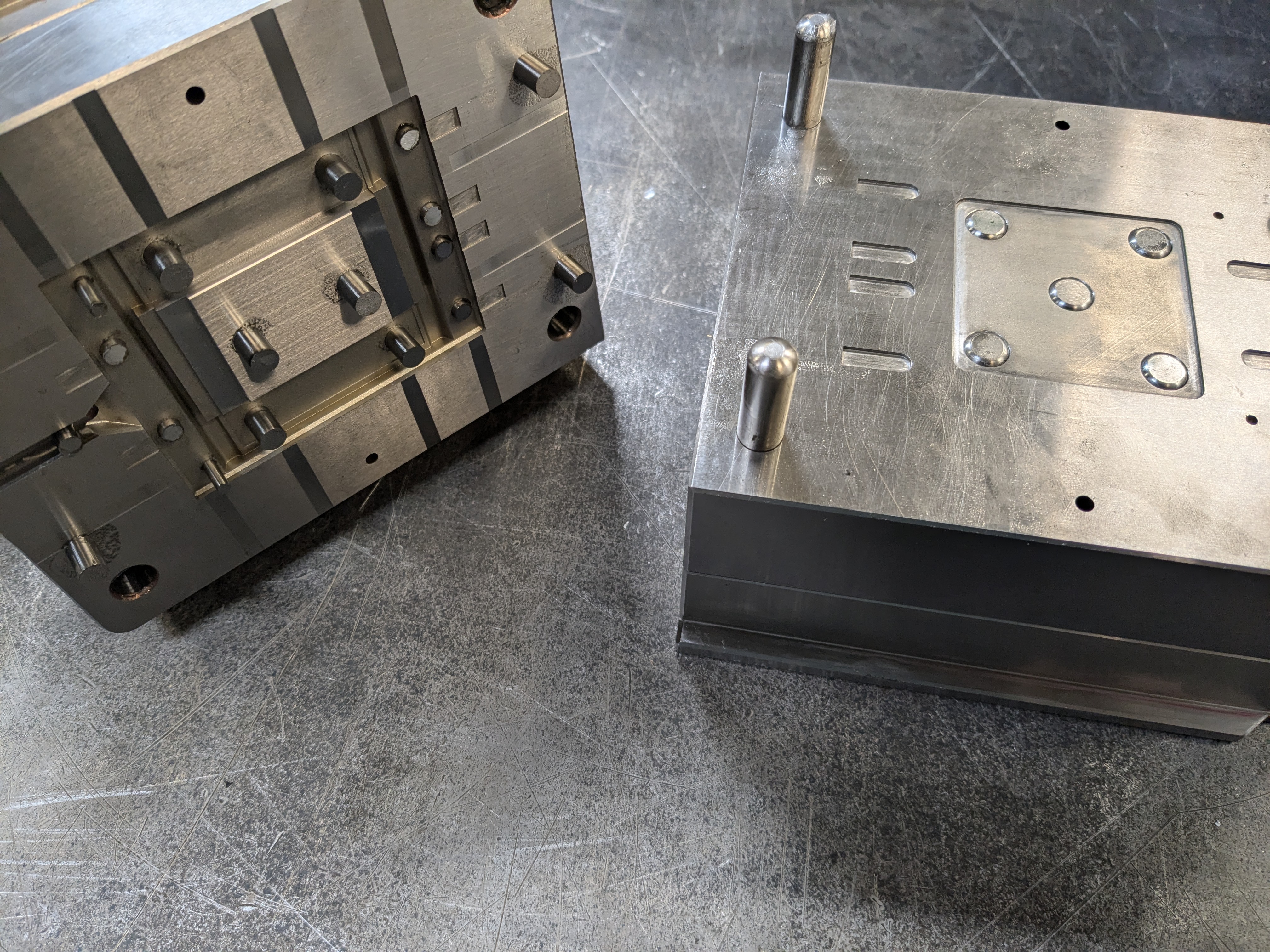

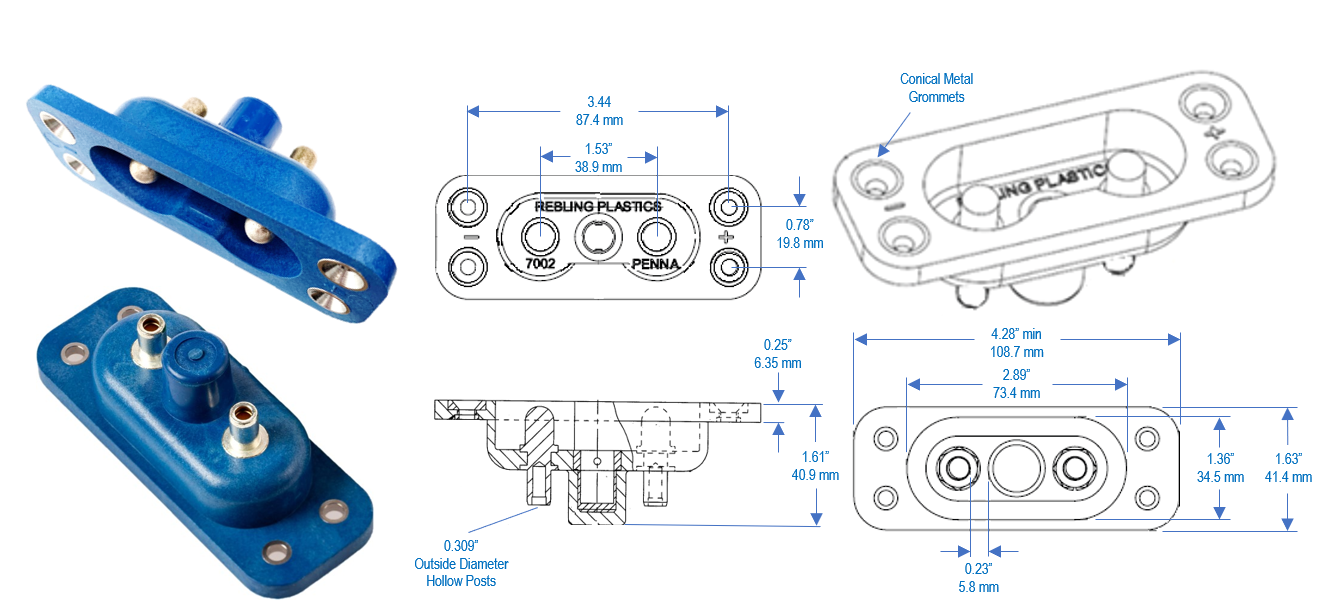

Plastic Injection Molds: Our state-of-the-art facility is equipped to design and manufacture plastic injection molds that meet the exact specifications of our clients. From concept to production, we ensure every mold is built to last, delivering precision and reliability.

Dies: We manufacture a wide range of dies for various applications in the defense and firearms industries. Our dies are crafted with precision engineering to ensure durability and performance in the most demanding applications.

Fixtures: Custom fixtures are essential for ensuring the accuracy and repeatability of manufacturing processes. We design and build fixtures tailored to your specific needs, enhancing efficiency and quality in your production line.

Gauges: Precision gauges are critical for maintaining the highest standards of quality control. We produce custom gauges that provide accurate measurements, ensuring your products meet stringent industry requirements.

Repair Services: In addition to manufacturing, we offer comprehensive repair services for molds, dies, fixtures, and gauges. Our skilled technicians can restore your equipment to optimal performance, minimizing downtime and extending the life of your tools.

Industries We Serve:

Defense Industry: We are proud to support the defense industry with precision-manufactured tools and dies that meet the highest standards of quality and reliability. Our products are designed to perform under the most challenging conditions.

Firearms: Precision is paramount in the firearms industry. Our expertise in manufacturing and repairing molds, dies, fixtures, and gauges ensures that every component meets the exacting standards required for safety and performance.

Munitions: The munitions industry demands absolute precision and consistency. Our custom-manufactured tools and dies are engineered to deliver superior results, ensuring the highest levels of accuracy and reliability.

Why Choose Tactical Tool & Die?

Experience: With decades of industry experience, we bring unparalleled expertise to every project.Quality: We are committed to delivering the highest quality products and services, adhering to strict industry standards.

Customization: Our solutions are tailored to meet the unique needs of each client, ensuring optimal performance and efficiency.

Innovation: We invest in the latest technology and techniques to stay at the forefront of the industry.

Customer Service: Our dedicated team is here to support you every step of the way, from initial consultation to ongoing maintenance and repair.

Contact Us Today!