Thermoset

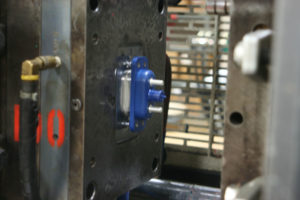

Thermoset plastics have been molded by Rebling for over 50 years. Examples of thermosetting plastics include Epoxy, Phenolic, and DAP. Rebling uses both the transfer and plastic injection molding processes for thermoset moldings.

Thermoset plastics have been molded by Rebling for over 50 years. Examples of thermosetting plastics include Epoxy, Phenolic, and DAP. Rebling uses both the transfer and plastic injection molding processes for thermoset moldings.

Unlike Nylon and other thermoplastics, thermoset plastic materials, during the molding cycle, undergo an irreversible chemical reaction or cure brought on by heat, pressure, and time. Once cured, thermoset plastic materials cannot be reshaped by melting and reprocessing as is the case for thermoplastics. Cured thermosets possess a highly cross-linked chemical structure enabling them to retain their mechanical and electrical properties as well as dimensional control over a wide temperature range. All thermosets molded by Rebling undergo a "deflashing" process after molding. This deflashing operation eliminates the undesirable excess material that by design is evident on parting lines and vent passages.

Epoxy Thermoset Material

Epoxy molding compounds are characterized by their long flow length and the ability to flow through thin cross-sections, filling minute details. This flow characteristic is particularly beneficial for encapsulation as there is less pressure required on the material during the molding cycle and therefore less pressure on the internal components of the device to be encapsulated.

The outstanding dielectric properties of epoxy combined with the low pressure molding requirements are the reasons epoxies are frequently specified for encapsulation of electrical devices, semi-conductor devices, transformers, and other electrical/electronic apparatus. Epoxies have a recommended shelf life as received from the material supplier. To insure maximum shelf life, Rebling stores epoxy molding compounds in refrigerated storage units. Epoxies are available formulated with various fillers including glass and minerals at various concentrations.

Phenolic Thermoset Material

Phenolic, the oldest polymer, is known for its excellent high temperature resistance. When properly post cured, some heat resistant phenolics can withstand up to a 550°F operating environment. Phenolic molded parts exhibit a glossy finish and a high surface hardness. As with other plastic materials, phenolics can be compounded with various fillers to alter the material's properties. These include wood flour, minerals, and glass fiber reinforcement. Phenolics are used in applications such as rocket motors, electrical motor brush holders, handles for cook wear, and wherever plastics need to operate at elevated temperatures.

Diallyl Phthalate, commonly referred to as DAP, exhibits outstanding electrical insulating properties particularly at high humidity and high temperatures environments. While not as heat resistant as phenolic, DAP can operate continuously at temperatures as high as 450°F. DAP is typically available in flame retardant grades including ratings of UL 94V-O in cross sections as small as .062 inches. End uses include coil bobbins, connectors, and circuit breakers.

Rebling has a significant amount of insert molding experience employing epoxy, phenolic and DAP thermoset resins. Rebling can provide a turnkey thermoset material service including design and procurement of mold(s), inserts, and molding compounds, as well as post curing, deflashing, and secondary operations. Rebling also has preforming equipment to compress the molding compounds into solid shapes suitable for dielectric preheating.

Mold temperatures for thermoset plastic materials typically are in excess of 300°F, so inserts must be able to withstand this molding temperature and the increase in temperature caused by the exothermic reaction that takes place during the cure cycle. Electrical devices incorporating solder connections and tin plated metal components are examples of inserts that could be damaged during the molding cycle if temperatures are too high.

Rebling engineers are available for consultation and recommendations on thermoset materials, processes, and critical molding requirements.

Diallyl Phthalate (DAP)

Diallyl Phthalate, commonly referred to as DAP, exhibits outstanding electrical insulating properties, particularly in high humidity and high temperatures environments. While not as heat resistant as phenolic, DAP can operate continuously at temperatures as high as 450°F. DAP is typically available in flame retardant grades including ratings of UL 94V-O in cross sections as small as .062 inches. End uses include coil bobbins, connectors, and circuit breakers.

Diallyl Phthalate, commonly referred to as DAP, exhibits outstanding electrical insulating properties, particularly in high humidity and high temperatures environments. While not as heat resistant as phenolic, DAP can operate continuously at temperatures as high as 450°F. DAP is typically available in flame retardant grades including ratings of UL 94V-O in cross sections as small as .062 inches. End uses include coil bobbins, connectors, and circuit breakers.

Rebling has been using DAP thermoset material for over the past 30 years using transfer and compression molding techniques. Rebling mostly uses this material in electrical interconnects (connectors, switches, etc). DAP is available in short and long glass fiber filled grades with limited color choices. DAP parts display outstanding stability even under load, along with good electrical/physical properties. Dielectric strength hold up even under the harshest environmental conditions. DAP is non-corrosive to inserts and resistant to weathering, fungus, and most solvents.

DAP plastics injection molding design

While DAP can be molded with thicker sections than thermoplastic materials, a thicker wall will make for a longer cycle time. When designing a new part, design engineers should consider switching to modern high temperature thermoplastics such as PPS, PEEK, or PEI which have much lower processing costs.

Properties of Molded Phenolic

Properties of Molded Phenolic

Properties of Molded Phenolic

Phenolic was the first plastic material molded by Rebling. Since 1961, Rebling has continued to mold this heat resistant thermoset plastic using both the transfer and injection molding processes.

The ability of phenolic to maintain its mechanical and electrical properties at high operating temperatures is the principal reason for its use today. When properly molded and post cured, some phenolics can withstand a 550°F continuous operating environment. Rebling utilizes several industrial ovens for post curing operations.

Prices for phenolic compounds start at $1.00 per pound and are attractively priced compared to expensive high temperature thermoplastics. This temperature resistant material is used in applications such as handles for cookware, car ashtrays, rocket motor housings, electrical motors components such as brush holders, and wherever resistance to high temperatures is required.

Phenolic molding compounds are available in single and two stage compounds. Single stage compounds are produced without ammonia and are ideal for insert molding metal components where metal corrosion is a concern. Phenolic molding compounds are available in numerous formulations where both the filler and the percentage of filler are varied to alter the properties of the molded part. Mineral and glass fillers are used to improve heat resistance; cotton flock fillers are used to improve impact strength, and glass fillers are used to improve mechanical strength and stiffness. Specialty fillers such as carbon fiber and lubricants such as PTFE are also available.

Phenolic molding compounds are available in limited colors. Most are available in black and brown, some also in red and green.

Many grades of phenolic have UL 94V 0 approval and a UL Relative Thermal Index typically 150°C, some compounds to 180°C.

While the cost of these compounds is attractive, processing times are significantly higher than thermoplastics. Cycle times can range from 30 seconds to several minutes depending on part geometry and material selection. Unlike thermoplastics which transform from a viscous liquid and solidify by cooling down in the mold, phenolic materials undergo an exothermic chemical reaction or cure. After molding, the parts must go through a deflashing operation also adding to the final part cost. Phenolic materials cannot be reground and reprocessed.

Phenolics have excellent chemical resistance to organic and halogenated solvents such as carbon tetrachloride. They are attacked by inorganic bases.

Design of Molded Phenolic Parts

Draft and tolerances should be specified on part drawings indicating maximum and minimum sizes for sections at each end of the taper. The drawing should also indicate whether or not tapers are included in the tolerances and note which end of a taper has a critically fixed size. Gate locations should be identified as well as any areas that are to be free of ejector pin marks.

Maintaining uniform cross sectional thicknesses to avoid sink marks by coring is not as critical for thermoset phenolics, since they do not readily show sink marks. However, parts with heavy cross sections require longer cycle times and are subject to increased warpage.

Rebling design engineers are prepared to provide design assistance to insure the successful outcome of your project.

Secondary operations

Phenolic parts can be bonded or mechanically assembled. Metal inserts can be molded in or pressed in after assembly. Decorating is typically limited to silk screening.